- Concrete Microstructure Properties And Materials Pdf Creator Online

- Physical Properties Of Materials Pdf

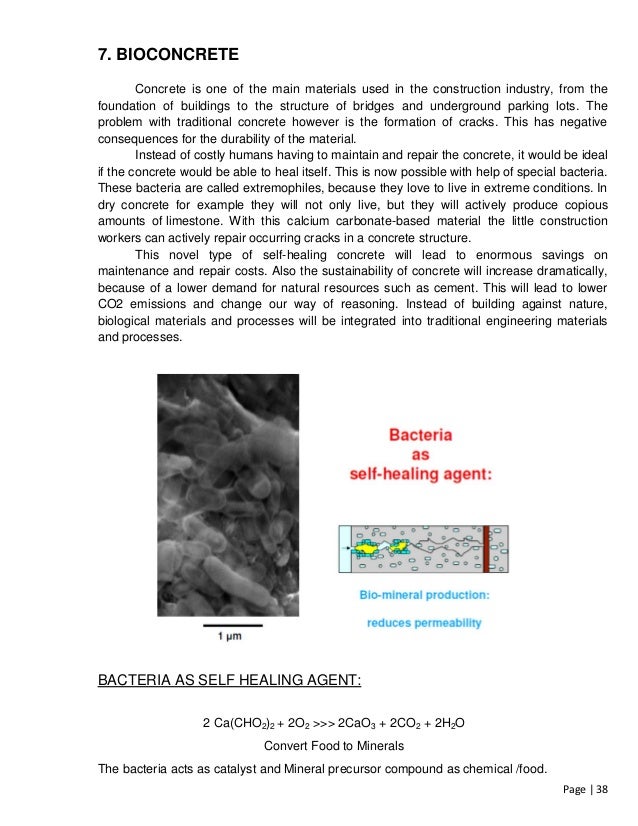

Pozzolanic materials such as silica fume and/or other pozzolanic materials should be incorporated with the Portland cement to improve the microstructure of concrete to improve the permeation properties and durability. [PDF] The Old World And America.pdf Concrete microstructure properties and materials - Now in its Third Edition, Plastics is the key text for senior students studying the science and engineering of plastic materials. Starting from microstructure.

1, Windows 8, Windows 7, Windows Vista, Windows Server 2. Simply double- click the downloaded file to install it. This document describes system requirements, new features, resolved caveats, known caveats and workarounds for Cisco UCS Manager software Release 2.2. Driver Pci System Peripheral Windows 98 Vmware Fusion Download UpdateStar is compatible with Windows platforms. UpdateStar has been tested to meet all of the technical requirements to be compatible with Windows 10, 8.1, Windows 8. The VMware Knowledge Base provides support solutions. Windows Me,Windows 98. Windows detects an Intel 82371EB. Pentium Processor to PCI bridge. Go to C: Windows System for the. I didn't worry because I knew Windows 98 had no driver for the sound. Problem installing sound card driver in Windows. Jul 18, 2013 Windows 98 - unidentified device drivers. The ethernet controller uses AMD PCNET drivers - I think they should be on the Windows install disk, but if not, Google may be able to help. The 'PCI System Peripheral' is the VMCI bus device - this does not work on Windows 98. Windows 98 vmware youtube. Jun 07, 2012 Re: Vmware Windows 98 Pci System Peripheral Post by Detective » Thu Jun 07, 2012 3:21 am Below you can download vmware windows 98 pci system peripheral driver for Windows.

Mp3 songs hindi. Please Note: Before downloading you can preview any song by mouse over the Play button and click Play or Click to Download button to download hd quality mp3 files. Now we recommend you to Download first result ச ல ல வ ட வ ள ள ந லவ Solli Vidu Velli Nilave Video Song HD Ilaiyaraja Mano Swarnalatha MP3 which is uploaded by Tamil Cinema of size 6.62 MB, duration 5 minutes and 2 seconds and bitrate is 192 Kbps. For your search query Unnudaiya MP3 we have found 1000000 songs matching your query but showing only top 10 results. First search results is from YouTube which will be first converted, afterwards the file can be downloaded but search results from other sources can be downloaded right away as an MP3 file without any conversion or forwarding.

-

Statistical summary of world rubber situation (2013) http://www.rubberstudy.com/documents/WebSiteData_2.0.pdf. Accessed 02 March 2014

-

Karger-Kocsis J, Mészáros L, Bárány T (2013) Ground tyre rubber (GTR) in thermoplastics, thermosets and rubbers. J Mater Sci 48:1–38. doi:10.1007/s10853-12-6564-2CrossRefGoogle Scholar

-

Rubber Manufacturers Association (2013) US scrap tire management summary 2005–2009. WashingtonGoogle Scholar

-

The recycling industry: a global view (2003) http://www.irevna.com/pdf/Industry%20report.pdf. Accessed 15 February 2014

-

Nehdi M, Khan A (2001) Cementitious composites containing recycled tire rubber: an overview of engineering properties and potential application. Cem Concr Aggr 23:3–10. doi:10.1520/CCA10519JGoogle Scholar

-

Meyer C (2009) The greening of the concrete industry. Cem Concr Comp 31:601–605. doi:10.1016/j.cemconcomp.2008.12.010CrossRefGoogle Scholar

-

Reschner K (2008) Scrap tire recycling. A summary of prevalent disposal and recycling methods. Entire-Engineering, BerlinGoogle Scholar

-

Tantala MW, Lepore JA, Zandi I (1996) Quasi-elastic behavior of rubber included concrete. In: 12th international conference on solid waste technology and management, Philadelphia, PAGoogle Scholar

-

Siddique R, Naik TR (2004) Properties of concrete containing scrap-tire rubber—an overview. Waste Manag 24:563–569. doi:10.1016/j.wasman.2004.01.006CrossRefGoogle Scholar

-

Ye Z, Kong X, Yu J, Wei L (2003) Microstructure and properties of desulfurized crumb rubber modified bitumen. J Wuhan Univ Tech Mater Sci Ed 18:83–85. doi:10.1007/BF02835097Google Scholar

-

Paul J (1985) Encyclopedia of polymer science and engineering. 14:787–802Google Scholar

-

Siddique R (2008) Waste materials and by-products in concrete. Springer, BerlinGoogle Scholar

-

Sunthonpagasit N, Duffey MR (2004) Scrap tires to crumb rubber: feasibility analysis for processing facilities. Resour Conser Recycl 40:281–299. doi:10.1016/S0921-3449(03)00073-9CrossRefGoogle Scholar

-

Shu X, Huang B (2013) Recycling of waste tire rubber in asphalt and Portland cement concrete: an overview. Constr Build Mater. doi:10.1016/j.conbuildmat.2013.11.027Google Scholar

-

Diaconescu RM, Barbuta M, Harja M (2013) Prediction of properties of polymer concrete composite with tire rubber using neural networks. Mater Sci Eng B 178:1259–1267. doi:10.1016/j.mseb.2013.01.014CrossRefGoogle Scholar

-

Suparat T (2013) Waste tyre management in Thailand: a material flow analysis approach. Dissertation, Asian Institute of Technology, ThailandGoogle Scholar

-

Nakao Y, Yamamoto K (2002) Waste tire and its collection systems. In: Nippon Steel technical report no. 86Google Scholar

-

Huynh H, Raghavan D (1997) Durability of simulated shredded rubber tire in highly alkaline environments. Adv Cem Bas Mater 6:138–143. doi:10.1016/S1065-7355(97)90021-3CrossRefGoogle Scholar

-

Lo Presti D (2013) Recycled tyre rubber modified bitumens for road asphalt mixtures: a literature review. Con Build Mat 49:863–881. doi:10.1016/j.conbuildmat.2013.09.007CrossRefGoogle Scholar

-

Epps JA (1994) Use of recycled tires in highways. Synthesis of Highway Practice 198, Transportation Research Board, National Research Council, WashingtonGoogle Scholar

-

Khatib ZK, Bayomy FM (1999) Rubberized Portland cement concrete. ASCE J Mater Civ Eng 11:206–213. doi:10.1061/(ASCE)0899-1561(1999)11:3(206CrossRefGoogle Scholar

-

Huang B, Li G, Pang S, Eggers J (2004) Investigation into waste tire rubber-filled concrete. ASCE J Mater Civ Eng 16:187–194. doi:10.1061/(ASCE)0899-1561(2004)16:3(187CrossRefGoogle Scholar

-

Lo Presti D, Airey G, Partal P (2012) Manufacturing terminal and field bitumen-tyre rubber blends: the importance of processing conditions. Pro Soc Behav Sci 53:485–494. doi:10.1016/j.sbspro.2012.09.899CrossRefGoogle Scholar

-

Adams C, Amos AD, Shuler S (1985) Asphalt rubber binder laboratory performance. Report FHWA/TX-8571, 347-1F, Department of Highways and Public Transportation, TexasGoogle Scholar

-

Wu S, Ye Q, Li N (2008) Investigation of rheological and fatigue properties of asphalt mixtures containing polyester fibers. Constr Build Mater 22:2111–2115. doi:10.1016/j.conbuildmat.2007.07.018CrossRefGoogle Scholar

-

Rodriguez Alloza AM, Gallego J, Pérez I, Bonati A, Giuliani F (2014) High and low temperature properties of crumb rubber modified binders containing warm mix asphalt additives. Constr Build Mater 53:460–466. doi:10.1016/j.conbuildmat.2013.12.026CrossRefGoogle Scholar

-

Fedroff D, Ahmad S, Savas BZ (1996) Mechanical properties of concrete with ground waste tire rubber. Trans Res Rec 1532:66–72. doi:10.3141/1532-10CrossRefGoogle Scholar

-

Liu H, Chen Z, Wang W, Wang H, Hao P (2013) Investigation of the rheological modification mechanism of crumb rubber modified asphalt (CRMA) containing TOR additive. Constr Build Mater. doi:10.1016/j.conbuildmat.2013.11.031Google Scholar

-

Seo Kim H, Geiger A, Amirkhanian SN, Soon Park T, Woo Kim K (2008) Effects of asphalt ratios on properties of crumb rubber modified asphalts. In: Proceedings of the 6th international conference on road and airfield pavement technology, Sapporo JapanGoogle Scholar

-

Abdelrahman MA, Carpenter SH (1998) Controlling low temperature properties of asphalt rubber binders. In: Proceedings of the 2nd transportation specialty conference, Canadian Society of Civil Engineering, Halifax, Nova Scotia, CanadaGoogle Scholar

-

Hernández-Olivares F, Barluenga G (2004) Fire performance of recycled rubber-filled high-strength concrete. Cem Concr Res 34:109–117. doi:10.1016/S0008-8846(03)00253-9CrossRefGoogle Scholar

-

Ganjian E, Khorami M, Maghsoudi A (2009) Scrap-tire-rubber replacement for aggregate and filler in concrete. Constr Build Mater 23:1828–1836. doi:10.1016/j.conbuildmat.2008.09.020CrossRefGoogle Scholar

-

Bravo M, De Brito J (2012) Concrete made with used tyre aggregate: durability-related performance. J Clean Prod 25:42–50. doi:10.1016/j.jclepro.2011.11.066CrossRefGoogle Scholar

-

Ali NA, Amos AD, Roberts M (1993) Use of ground rubber tires in portland cement concrete. In: Proceedings of the international conference on concrete 2000, University of Dundee, Scotland, p 379–390Google Scholar

-

Rostami H, Lepore J, Silverstraim T, Zundi I (1993) Use of recycled tires in concrete. In: International conference on concrete 2000, University of Dundee, Scotland, p 391–399Google Scholar

-

Eldin NN, Senouci AB (1993) Rubber-tire particles as concrete aggregates. ASCE J Mater Civ Eng 5:478–496. doi:10.1061/(ASCE)0899-1561(1993)5:4(478CrossRefGoogle Scholar

-

Topçu İB (1995) The properties of rubberized concrete. Cem Concr Res 25:304–310. doi:10.1016/0008-8846(95)00014-3CrossRefGoogle Scholar

-

De Brito J, Saikia N (2013) Recycled aggregate in concrete: use of industrial, construction and demolition waste. Springer, LondonCrossRefGoogle Scholar

-

Topçu İB, Avcular N (1997) Analyses of rubberized concrete as a composite material. Cem Concr Res 27:1135–1139. doi:10.1016/S0008-8846(97)00115-4CrossRefGoogle Scholar

-

Topçu İB (1997) Assessment of the brittleness index of rubberized concretes. Cem Concr Res 27:177–183. doi:10.1016/S0008-8846(96)00199-8CrossRefGoogle Scholar

-

Liu F, Zheng W, Li L, Feng W, Ning G (2013) Mechanical and fatigue performance of rubber concrete. Constr Build Mater 47:711–719. doi:10.1016/j.conbuildmat.2013.05.055CrossRefGoogle Scholar

-

Toutanji HA (1996) The use of rubber tire particles in concrete to replace mineral aggregates. Cem Concr Comp 18:135–139. doi:10.1016/0958-9465(95)00010-0CrossRefGoogle Scholar

-

Ho AC, Turatsinze A, Hameed R, Vu DC (2012) Effects of rubber aggregates from grinded used tyres on the concrete resistance to cracking. J Clean Prod 23:209–215. doi:10.1016/j.jclepro.2011.09.016CrossRefGoogle Scholar

-

Khaloo AR, Dehestani M, Rahmatabadi P (2008) Mechanical properties of concrete containing a high volume of tire-rubber particles. Waste Manag 28:2472–2482. doi:10.1016/j.wasman.2008.01.015CrossRefGoogle Scholar

-

Issa CA, Salem G (2013) Utilization of recycled crumb rubber as fine aggregates in concrete mix design. Constr Build Mater 42:48–52. doi:10.1016/j.conbuildmat.2012.12.054CrossRefGoogle Scholar

-

Segre N, Joekes I (2000) Use of tire rubber particles and addition to cement paste. Cem Concr Res 30:1421–1425. doi:10.1016/S0008-8846(00)00373-2CrossRefGoogle Scholar

-

Raghavan D, Huynh H, Ferraris CF (1998) Workability, mechanical properties and chemical stability of a recycled tyre rubber filled cementitious composite. J Mater Sci 33:1745–1752. doi:10.1023/A:1004372414475CrossRefGoogle Scholar

-

Mehta PK, Gjorv OE (1982) Properties of portland cement concrete containing fly ash and condensed silica fume. Cem Concr Res 12:587–595. doi:10.1016/0008-8846(82)90019-9CrossRefGoogle Scholar

-

Huang B, Shu X, Cao J (2013) A two-staged surface treatment to improve properties of rubber modified cement composites. Constr Build Mater 40:270–274. doi:10.1016/j.conbuildmat.2012.11.014CrossRefGoogle Scholar

-

Güneyisi E, Gesoğlu M, Özturan T (2004) Properties of rubberized concretes containing silica fume. Cem Concr Res 34:2309–2317. doi:10.1016/j.cemconres.2004.04.005CrossRefGoogle Scholar

-

Pelisser F, Zavarise N, Longo TA, Bernardin AM (2011) Concrete made with recycled tire rubber: effect of alkaline activation and silica fume addition. J Clean Prod 19:757–763. doi:10.1016/j.jclepro.2010.11.014CrossRefGoogle Scholar

-

Navarro FJ, Partal P, Boza FM, Valencia C, Gallegos C (2002) Rheological characteristics of ground tire rubber-modified bitumens. Chem Eng J 89:53–61. doi:10.1016/S1385-8947(02)00023-2CrossRefGoogle Scholar

-

Moro FJL, Moro MC, Olivares FH, Schultz BW, Fernández MA (2013) Microscopic analysis of the interaction between crumb rubber and bitumen in asphalt mixtures using the dry process. Constr Build Mater 48:691–699. doi:10.1016/j.conbuildmat.2013.07.041CrossRefGoogle Scholar

-

Xiang L, Cheng J, Que G (2009) Microstructure and performance of crumb rubber modified asphalt. Constr Build Mater 23:3586–3590. doi:10.1016/j.conbuildmat.2009.06.038CrossRefGoogle Scholar

-

Albano C, Camacho N, Reyes C, Feliu JL, Hernández M (2005) Influence of scrap rubber addition to portland I concrete composites: destructive and non-destructive testing. Comp Struct 71:439–446. doi:10.1016/j.compstruct.2005.09.037CrossRefGoogle Scholar

-

Turatsinze A (2005) Mechanical characterization of cement-based mortar incorporating rubber aggregates from recycled worn tyres. Build Environ 40:221–226. doi:10.1016/j.buildenv.2004.05.012CrossRefGoogle Scholar

-

Bignozzi MC, Sandrolini F (2006) Tyre rubber waste recycling in self-compacting concrete. Cem Concr Res 36:735–739. doi:10.1016/j.cemconres.2005.12.011CrossRefGoogle Scholar

-

Turki M, Bretagne E, Rouis MJ, Quéneudec M (2009) Microstructure, physical and mechanical properties of mortar-rubber aggregates mixtures. Constr Build Mater 23:2715–2722. doi:10.1016/j.conbuildmat.2008.12.019CrossRefGoogle Scholar

-

Li G, Stubblefield MA, Garrick G, Eggers J, Abadie C, Huang B (2004) Development of waste tire modified concrete. Cem Concr Res 34:2283–2289. doi:10.1016/j.cemconres.2004.04.013CrossRefGoogle Scholar

-

Li Z, Li F, Li JS (1998) Properties of concrete incorporating rubber tyre particles. Mag Concr Res 50:297–304. doi:10.1680/macr.1998.50.4.297CrossRefGoogle Scholar

-

Shen W, Shan L, Zhang T, Ma H, Cai Z, Shi H (2013) Investigation on polymer-rubber aggregate modified porous concrete. Constr Build Mater 38:667–674. doi:10.1016/j.conbuildmat.2012.09.006CrossRefGoogle Scholar

-

Chou LH, Yang CK, Lee MT, Shu CC (2010) Effects of partial oxidation of crumb rubber on properties of rubberized mortar. Comp Part B 41:613–616. doi:10.1016/j.compositesb.2010.09.009CrossRefGoogle Scholar

-

Benazzouk A, Douzane O, Langlet T, Mezreb K, Roucoult JM, Quéneudec M (2007) Physico-mechanical properties and water absorbtion of cement composite containing shredded rubber wastes. Cem Concr Comp 29:732–740. doi:10.1016/j.cemconcomp.2007.07.001CrossRefGoogle Scholar

-

Benazzouk A, Douzane O, Quéneudec M (2004) Transport of fluids in cement-rubber composites. Cem Concr Comp 26:21–29. doi:10.1016/S0958-9465(02)00119-1CrossRefGoogle Scholar

-

Isayev AI (2013) Recycling of rubbers. In: The science and technology of rubber, 4th edn, Chapter 15, Elsevier, pp 697–764Google Scholar

-

Torgal FP, Ding Y, Jalali S (2012) Properties and durability of concrete containing polymeric wastes (tyre rubber and polyethylene terephthalate bottles): an overview. Constr Build Mater 30:714–724. doi:10.1016/j.conbuildmat.2011.11.047CrossRefGoogle Scholar

-

Reda Taha MM, El-Dieb AS, Abd El-Wahab MA, Abdel Hameed ME (2008) Mechanical, fracture, and microstructural investigations of rubber concrete. J Mater Civ Eng 20:640–649. doi:10.1061/(ASCE)0899-1561(2008)20:10(640CrossRefGoogle Scholar

-

Hernández Oliveras F, Barluenga G, Bollati M, Witoszek B (2002) Static and dynamic behavior of recycled tyre rubber-filled concrete. Cem Concr Res 32:1587–1596. doi:10.1016/S0008-8846(02)00833-5CrossRefGoogle Scholar

-

Holmes N, Dunne K, O’Donnell J (2014) Longitudinal shear resistance of composite slabs containing crumb rubber in concrete toppings. Constr Build Mater 55:365–378. doi:10.1016/j.conbuildmat.2014.01.046CrossRefGoogle Scholar

-

Segre N, Ostertag C, Monteiro P (2006) Effect of tire rubber particles on crack propagation in cement paste. Mater Res 9:311–320. doi:10.1590/S1516-14392006000300011CrossRefGoogle Scholar

Abstract

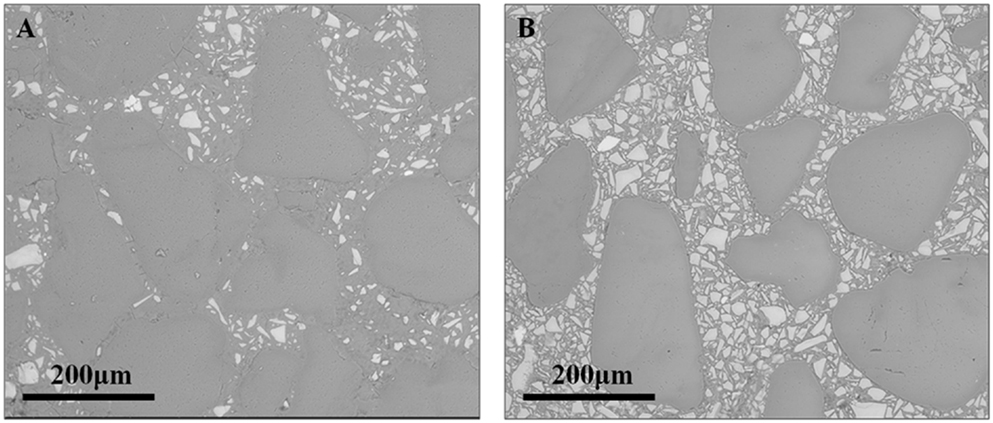

Morphology characteristics of mix aggregates with crushed air-cooled blast furnace slag (SCR) and crushed limestone (LCR) with 5–20 mm and 20–40 mm gradation were represented by numerical parameters including angularity number (AN) and index of aggregate particle shape and texture (IAPST). The effect of mix aggregates containing SCR on compressive strength and splitting tensile strength of concrete was investigated. Fracture characteristics of concrete, interfacial structure between aggregates and matrix were analyzed. The experimental results show that porous and rough SCR increases contact area with matrix in concrete, concave holes and micro-pores on the surface of SCR are filled by mortar and hydrated cement paste, which may increase interlocking and mechanical bond between aggregate and matrix in concrete. SCR can be used to produce a high-strength concrete with better mechanical properties than corresponding concrete made with LCR. The increase of AN and IAPST of aggregate may enhance mechanical properties of concrete.

Journal

Concrete Microstructure Properties And Materials Pdf Creator Online

Journal of Wuhan University of Technology-Mater. Sci. Ed. – Springer Journals

Physical Properties Of Materials Pdf

Published: Jul 14, 2012